It is common knowledge that 3D printing has become the technology of the future par excellence. In the meantime, the additive manufacturing process has also arrived in metal printing and is popular in many industries such as automotive, aerospace and medical technology. After all, the technology enables the relatively cost-effective production of components with very complex geometries. Reason enough for sinter specialist Schunk to help shape this trend. Schunk expert Tobias Franz Heusel and Eric Bader, Managing Director at machine manufacturer ExOne explain why the company relies on metal binder jetting and how customers benefit from this process.

Mr. Heusel, yesterday axial pressing - tomorrow 3D printing. It looks like things are on the move at Schunk in Thale?

Tobias Franz Heusel: That's right. 3D printing is the technology of the future and is used primarily in the automotive industry to reduce costs, time and weight in the production of complex components. If we still want to be an attractive development partner tomorrow, we have to use and further develop technologies that move our customers forward. We can no longer do this with our existing sintered metal components for combustion engines alone. That's why our goal is to integrate innovative 3D printing technologies into our existing series production and to open up new applications and markets with new products.

Which markets can you imagine?

Tobias Franz Heusel: On the one hand, these are of course still markets such as automotive and aerospace. On the other hand, 3D printing will bring us absolute flexibility in the future and thus the possibility of producing complex components for a wide range of industries. There is already interest from a machine manufacturer, for example, but components for the consumer sector, for white goods or the medical industry are also conceivable.

Is Schunk entering completely new territory when it comes to 3D printing? Or do you already have experience in this area?

Tobias Franz Heusel: As a materials specialist, Schunk is already working on this topic in various areas. Be it with 3D printing of ceramic materials or fiber composites. Here, we can use synergy effects within the company group and exchange experiences. We are also already working with 3D metal printing in sintering technology - in cooperation with Volkswagen. This means we have the option of printing components and then sintering them. In this way, both companies are learning from each other. In addition, we have been integrating a 3D printing technology known as composite extrusion modeling (CEM) into our metal powder injection molding series production for prototypes and very small series for some months now. Here, the printing process replaces injection molding with CEM shaping.

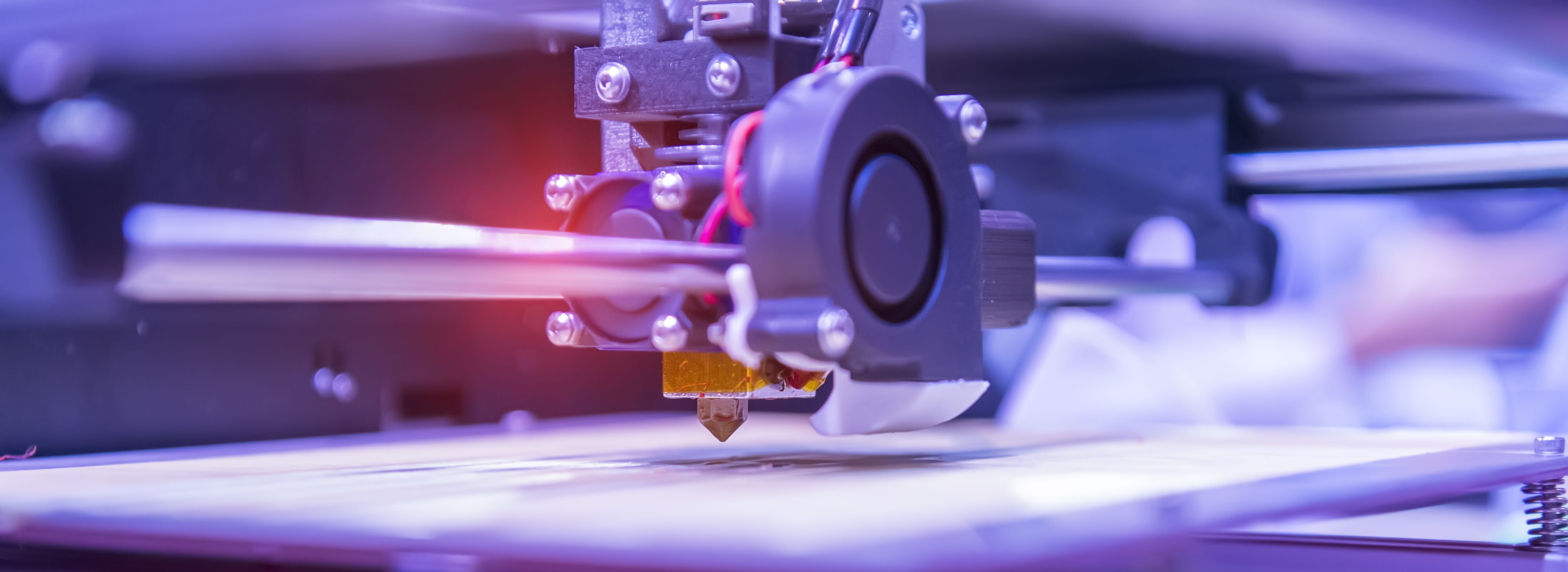

For the production of Binder Jet 3D printed metal parts Schunk relies on a X1 25Pro® metal printing system from ExOne.

(© ExOne GmbH)

You are talking about very small series here. But what does the future production of large series look like?

Tobias Franz Heusel: That is precisely our challenge. We produce here with two series technologies, axial pressing and metal injection molding (MIM), and thus manufacture quantities of 100,000 units and more - mainly for the automotive, but also for the aerospace industry. With the increasing move away from the traditional combustion engine and the shift to new types of drive, production volumes can vary. Our goal was therefore to be more flexible in testing and manufacturing with new equipment, using existing series production facilities and equipment, and to be able to produce new geometries for all types of drive types. The fact that we will be able to meet these demands in the future is a real technological milestone.

And what technology can meet your demands in the future?

Tobias Franz Heusel: We have opted for what is known as metal binder jetting, a very fast additive manufacturing process in which the metal powder - unlike in laser beam melting - is bonded together by means of a binder.

Why did you decide on metal binder jetting?

Tobias Franz Heusel: Metal Binder Jetting is the perfect solution for us because it offers our customers and us four important advantages:

- Low cost: Metal Binder Jetting is up to 100 times faster and therefore much more cost-efficient than other 3D printing processes, for example laser melting.

- High volumes: The technology is fast and cost-effective enough to be used to produce high volumes.

- Design freedom: With the 3D printing process, even complex geometries, such as undercuts, can be realized. Cost-intensive reworking is eliminated due to near-net-shape manufacturing. Design changes are possible without tooling costs.

- A wide range of materials: With this technology and our materials expertise, we can use the same materials that are already used in our series production. The wide selection for our customers includes: Copper, copper alloys, stainless steel, low alloy steel, tool steel, and nickel and cobalt based alloys.

Why is metal binder jetting so much faster than, for example, laser beam melting?

Tobias Franz Heusel: There are two reasons: First, the printing process is faster because the particles are bonded together by means of a binder and not fused as in laser beam melting. Secondly, laser beam melting requires a support geometry due to the stresses created by the melting process. This has to be removed at great expense after printing. Metal binder jetting does not require a support geometry. This has the additional advantage that not only can a single layer be printed, but the entire installation space can be utilized. In short, with Metal Binder Jetting we get more components in less time.

That's how the metal binder jetting technology works:

(© ExOne GmbH)

In order to establish this process at Schunk in the future, you are working together with the company ExOne. Why?

Tobias Franz Heusel: We have done extensive research in the area of metal binder jetting. The evaluation of various factors has shown that ExOne is the right partner to jointly establish metal binder jetting as a technology for large-scale production at our company. Not only does the company historically have the most experience in the field of binder jetting, but it also fits Schunk Sinter Metals in Thale with regard to its goals and ideas.

Asked the other way around, Mr. Bader: What makes Schunk an interesting partner for you?

Eric Bader: As the leading manufacturer for 3D printers with binder jetting technology, you want a partner at eye level with whom you can first clearly understand the needs of the market and then together cover them professionally. And this is exactly where Schunk excels as a material expert and with its decades of experience in sintering technology - both in metal powder injection molding and axial pressing. And this in the most demanding market sectors such as automotive and aerospace.

Subscribe to blog: