Earthing systems from Schunk - Reliable protection for modern drive technologies

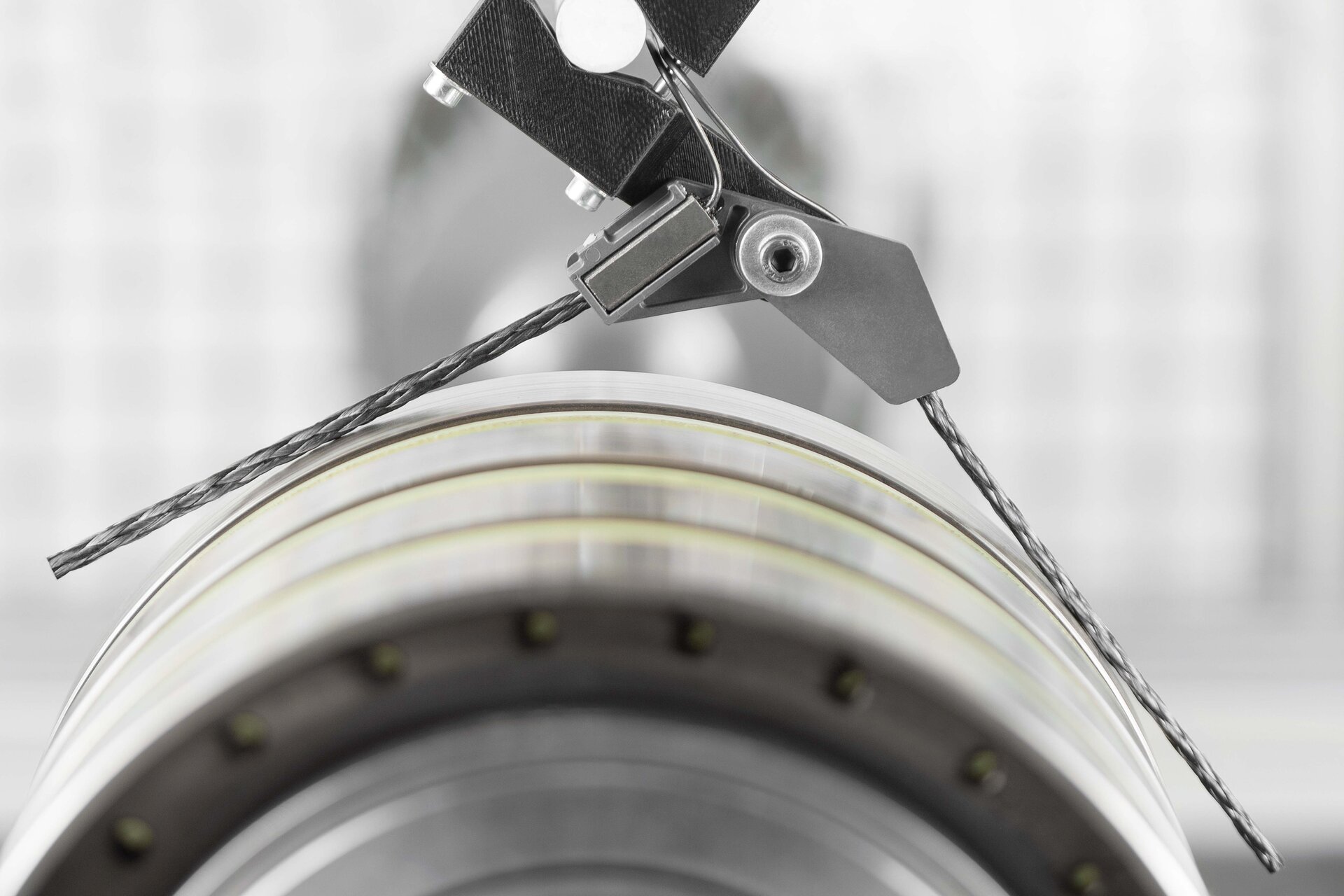

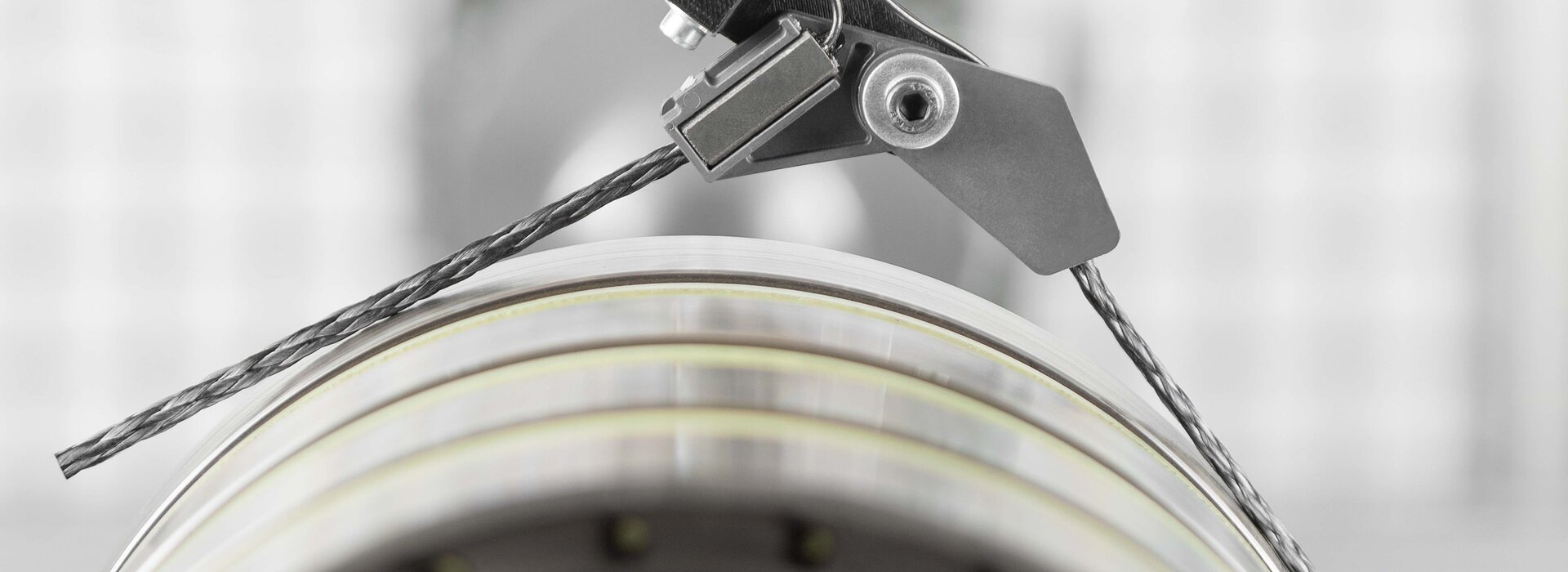

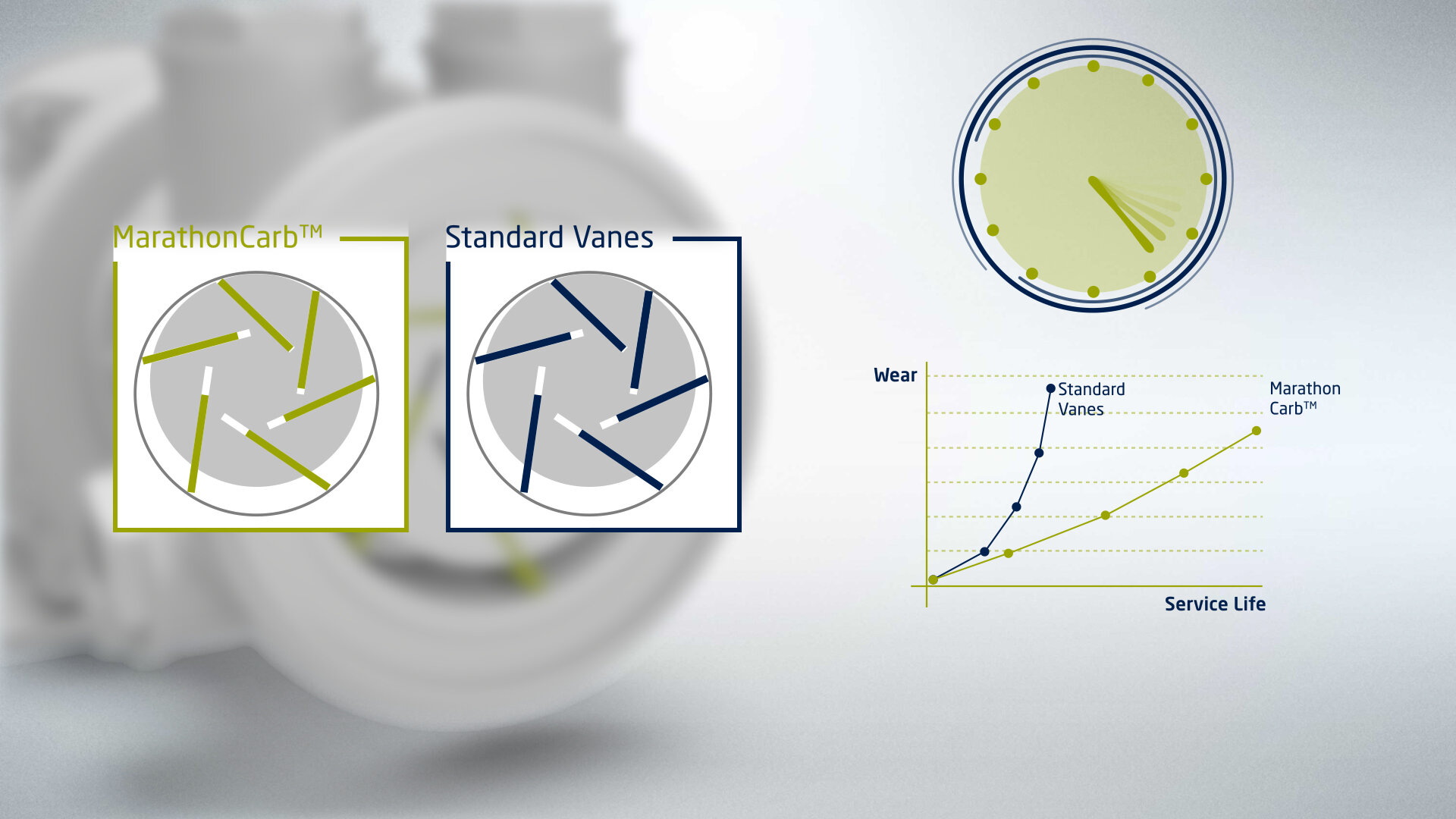

Parasitic shaft currents are among the most common causes of bearing damage in electric drive systems. Inadequate grounding can lead to costly failures – in rail transport, industrial production facilities, and electric mobility alike. The Schunk Group addresses this challenge with a comprehensive portfolio of grounding systems, ranging from traditional grounding contacts to innovative carbon-based solutions.