Graphite - The perfect material for conductivity measuring electrodes

Interview

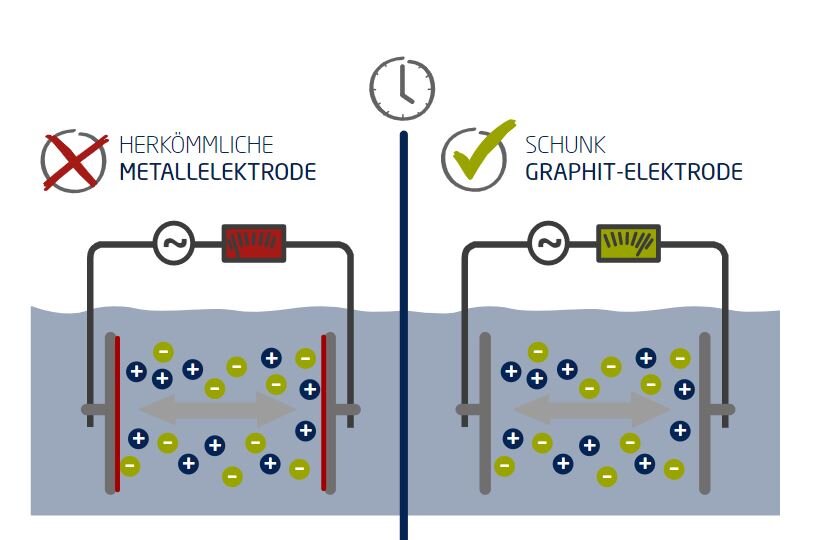

What distinguishes conductivity measuring electrodes made of graphite from metallic variants?

Stefan Günther: The special feature of conductivity measuring electrodes made of graphite is that no oxide layer forms on their surface that could falsify the measured value. Even when in contact with aggressive media, the properties of the graphite material remain constant and stable over the long term. Accordingly, graphite conductivity electrodes are ideally suited for applications in the chemical, pharmaceutical and food industries.

In addition, no biofilm forms on graphite, as bacteria and algae survive very poorly here. Our conductivity measuring electrodes therefore offer our customers advantages above all where a measuring device has to operate maintenance-free over long periods of time in remote or difficult-to-access locations and has to deliver accurate measuring results.

What is Schunk's standard for meeting its customers' high expectations for long-lasting conductivity measuring electrodes?

Stefan Günther: Simply put, our customers are looking for solutions that we deliver with our products. In order for this to succeed, customers can expect a development partner like Schunk to bring both extensive knowledge for their own field and technical understanding for the customer's field. This is the only way to create a customized solution that meets all requirements and stands out from one-size-fits-all products that are designed to meet needs only to a limited extent.

⇒ Here you can find more information about the advantages of our conductivity measurement electrodes.

Why can customers rely on Schunk to understand their problem and find a suitable solution?

Stefan Günther: Our customers expect us to provide a high quality product, competent advice and to be a reliable partner.

We meet our customers' quality demands through high quality standards and optional outgoing goods inspection according to customer specifications. Our experienced and competent teams in application technology, development and sales ensure competent advice.

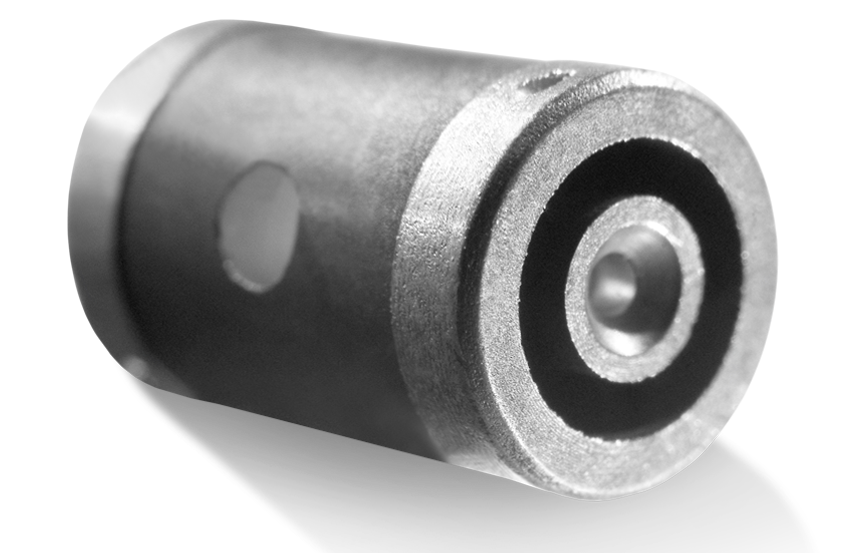

However, what distinguishes Schunk above all is its materials expertise. Schunk has been working with carbon and graphite materials for over 100 years. During this time, we have continuously developed our processes for manufacturing, quality assurance and processing. This means that we have very sound materials expertise, which we demonstrate in a wide range of products used in a wide variety of industries. For more than 20 years, our portfolio has also included conductivity measuring electrodes made of graphite.

But our customers benefit from more than just our decades of experience. Schunk's long-term corporate culture, which is geared toward financial independence, gives our customers security and makes us a reliable partner.

What exactly does the collaboration between Schunk and its customers look like?

Stefan Günther: Our colleagues from Sales and Application Engineering are available as the first point of contact for customer inquiries. They listen carefully in order to understand the customer's challenges and their needs exactly.

Depending on how complex the solution sought is and how far it deviates from established products and existing manufacturing processes, the Schunk team expands: developers and manufacturing specialists are added.

Once the solution is ready for production and commercially competitive, and all details regarding quality assurance, packaging and shipping, etc. have been clarified, customer service takes care of processing customer orders.

But that's not the end of our customer support. Of course, our team is still available after a product has gone into series production. This allows us to react quickly and flexibly to any change requests.

We would be happy to tackle your measurement technology challenges together with you.

Our experts look forward to your inquiry.

Comparison between conductivity measuring electrodes made of graphite and conventional measuring electrodes