Pilot project: Badenova for environmentally conscious energy solution

Sustainability is a top priority for the regional energy provider, and thanks to its location in sunny Breisgau in the southwest of Germany, the proportion of renewable energy flowing into Badenova's grid is high. Balancing the weather-related imbalance between energy generation and consumption, however, presents challenges for the company. In a pilot project, the company therefore tested the use of redox flow batteries. In our TechTalk with Schunk expert Dr. Hartmut Groß, Business Developer Dr. Malte Thoma from Badenova tells us what makes this storage technology interesting for energy providers, where the advantages lie compared to lithium-ion batteries, and how Schunk, as a manufacturer of graphite bipolar plates, can contribute to the development of this technology.

Our experts

About Dr. Malte Thoma

Dr. Malte Thoma is Team Leader Business Development at Badenova AG. After studying electrical engineering in Karlsruhe, he earned his doctorate with a thesis on smart grids at the Swiss Federal Institute of Technology in Zurich. He has more than 20 years of experience in the energy industry.

About Dr. Hartmut Gross

As Director New Business & Technology, Dr. Hartmut Groß and his team make a significant contribution to the development of new solutions for Schunk. One focus of his work is on energy storage systems. Hartmut Groß earned his doctorate in physics. Since then, he has been implementing his vision of generating business from new technologies, especially in the field of renewable energies.

Interview

Dr. Thoma, you work for the energy provider Badenova. What is your interest in stationary storage solutions?

Malte Thoma: Badenova is a regional energy provider based in Freiburg. For us, sustainability is not just a label, but a real business factor. Due to our geographical location, the share of renewable energy sources in our grid is growing more and more, especially from photovoltaic systems. Maintaining a stable energy supply is a major challenge for us. At Badenova, we have come to the conclusion that stationary battery storage can be helpful in ensuring this. We are primarily concerned here with maintaining voltage in the grid and avoiding overloads without having to shut down photovoltaic plants. We therefore already have stationary storage solutions in use as part of our pilot project.

Dr. Groß, why is Schunk interested in stationary storage solutions?

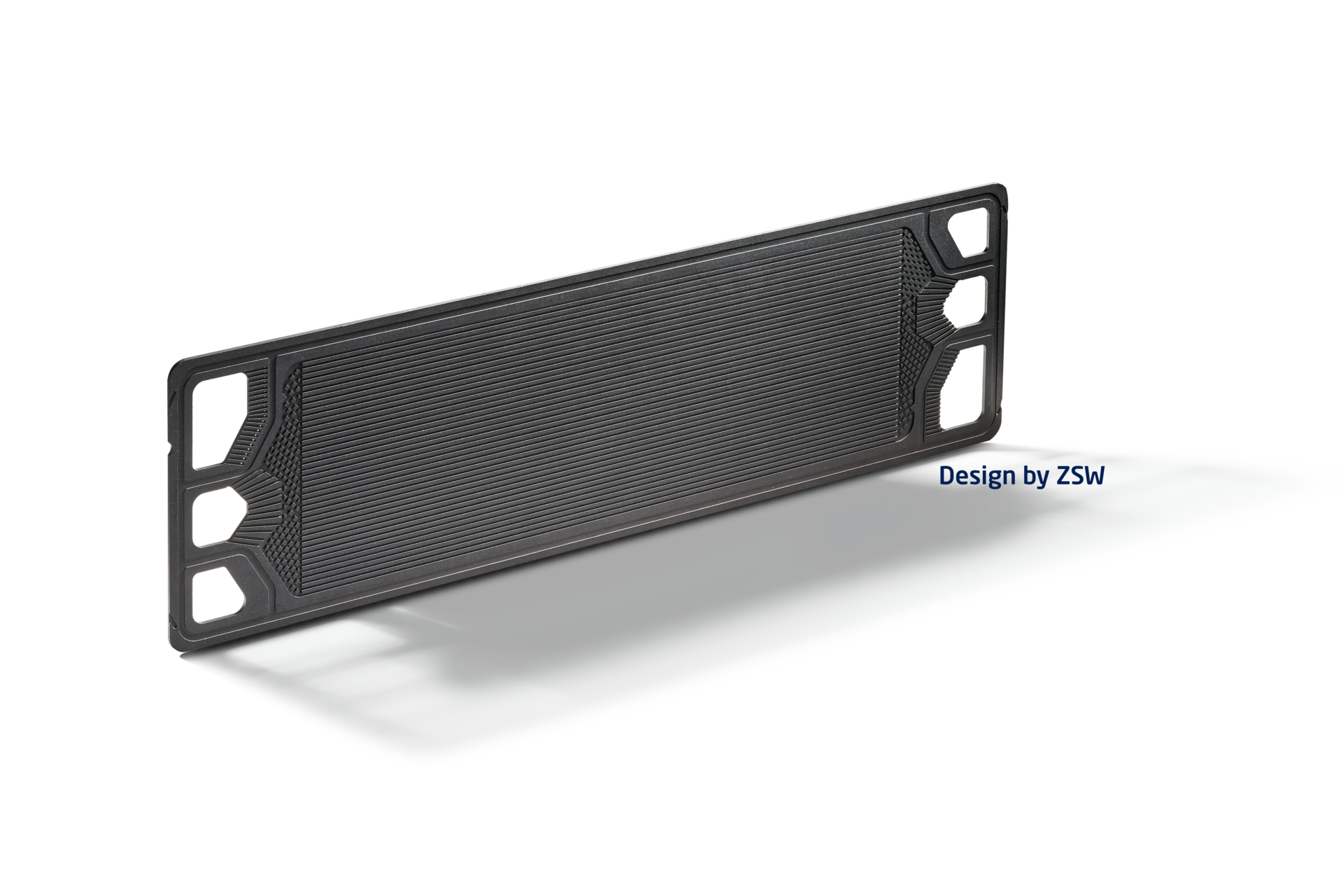

Hartmut Groß: I was an insider in the photovoltaic industry for many years and realized years ago that the increasing success of renewable energies requires energy storage solutions on a large scale. Schunk wants to contribute to this need with key components such as graphite-based bipolar plates for redox flow batteries.

Why are you dealing with redox flow batteries in particular with regard to your project, Dr. Thoma?

Malte Thoma: In our region, the sunny southwest of Germany, photovoltaics is the dominant renewable energy source. We have over 3,000 photovoltaic systems in our grid. This means that we do not have a constant energy production, but a very high one on sunny days, a low one when it is cloudy and none at all at night. There are also rapid and very strong fluctuations during the day, depending on the cloud cover. This imbalance between production and consumption must be balanced, and that is precisely our task as an energy provider. Our second challenge is that our power grid was built decades ago, when photovoltaics didn't even play a role. This means that large parts of the grid are not at all designed for decentralized energy generation. We are therefore testing advanced and intelligent approaches to address these challenges in addition to the classic grid enhancement.

How do you deal with these challenges? What is your solution?

Malte Thoma: We started a pilot project in 2019 and defined a total of six requirements for a storage solution:

- high reliability

- low maintenance requirements to save on service costs

- long service life (20,000 charge and discharge cycles for a service life of 20 years or longer)

- fire safety, to be flexible in installation locations

- competitive life cycle cost

In the end, we decided against lithium-ion technology and chose a redox flow battery from the regional supplier Storion Energy. In the meantime, we can look back on two years of operating experience with this technology.

Hartmut Groß: Against the background that battery solutions seem to be strongly dominated by lithium-ion batteries, this is a very interesting decision. For example, I just learned that the largest battery storage facility with a capacity of 400 megawatt hours is equipped with lithium-ion cells.

Our largest production site in Heuchelheim, with around 2000 employees, has also recently installed a battery storage system for peak load capping and had to purchase a lithium-ion solution, as no adequate commercial solutions for redox flow batteries are currently available.

Dr. Thoma, why do you think the share of redox flow batteries will continue to increase, even though lithium-ion batteries are more popular?

Malte Thoma: Yes, lithium-ion solutions do indeed dominate the market because they come from the booming electromobility sector. But we have to take into account our previously mentioned sustainability requirements. Lithium-ion batteries are made of materials such as cobalt, lithium, manganese or phosphorus. For our company, the ethics behind the mining and manufacturing process of the raw materials are becoming increasingly important. Lithium-ion batteries are also difficult to recycle. There is no convincing solution to separate the raw materials economically and sustainably. Secondary use of battery cells in stationary storage systems only shifts the problem. We are a long way from a true circular economy in this area. In addition, lithium-ion batteries have a fire problem that is not entirely negligible, which is not conducive to public acceptance.

And what about the service life of the batteries?

Malte Thoma: Yes, that's a good question. Everyone knows that lithium-ion batteries cannot be discharged 100 percent and that the available capacity decreases significantly over the years. The service life of each cell is limited to a total of no more than about 3000 charge/discharge cycles, which in our case could be exhausted after just seven to eight years. Then there would be nothing left but to accept a much lower storage capacity with degradation of the cells or to replace the old cells. But we wanted a lifetime of 20 years or more.

Interesting to know. And with that, what are the advantages of redox flow batteries from your point of view?

Malte Thoma: Redox flow batteries have many advantages:

- They can be discharged 100 percent.

- They are safe from a fire protection point of view, since they consist of about 80 percent water.

- The vanadium used in the electrolyte is not consumed during operation and can be 100 percent recycled at the end of its service life.

- The battery itself is virtually maintenance-free.

- Power and capacity (amount of energy) can be scaled independently.

Because of these advantages, I expect the market share of redox flow batteries for stationary use to increase. The share of renewable energy will grow and so will the demand for storage. In this large market, there will be niches for lithium-ion, redox-flow and hydrogen technology - always depending on the application and its scale. In addition, I expect that as demand increases and manufacturing takes place on a larger scale, the price per installed megawatt-hour will drop significantly. Similar to what we have already seen with lithium-ion batteries in recent years.

Hartmut Groß: This is a good point for us at Schunk. We are a supplier of graphite bipolar plates. As one of the key components of the stack, it determines the power density of the system. Our material has already been qualified by several redox flow battery manufacturers and has been proven for fuel cell applications for 20 years.

For pilot projects, we supply raw sheets of our compression molded grade, and customers machine the final shape. For series production, we can use customer-specific pressing tools, which saves post-processing and material losses due to mechanical processing from larger raw plates.

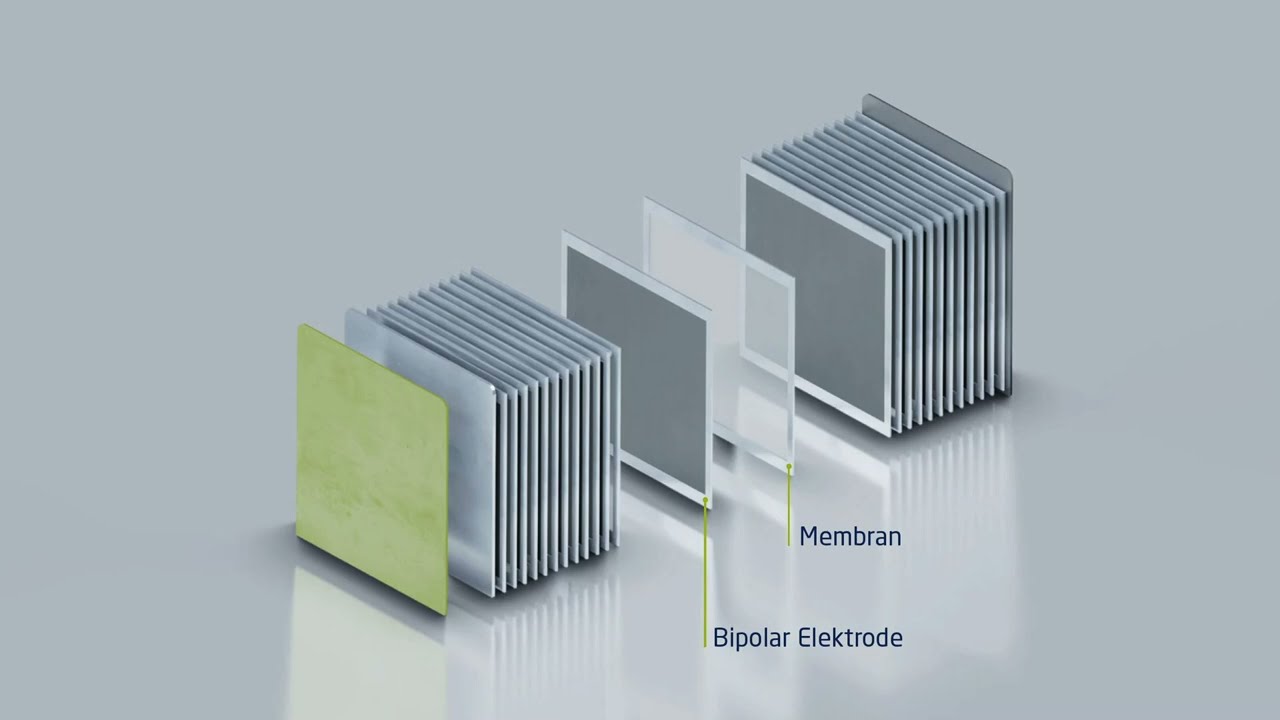

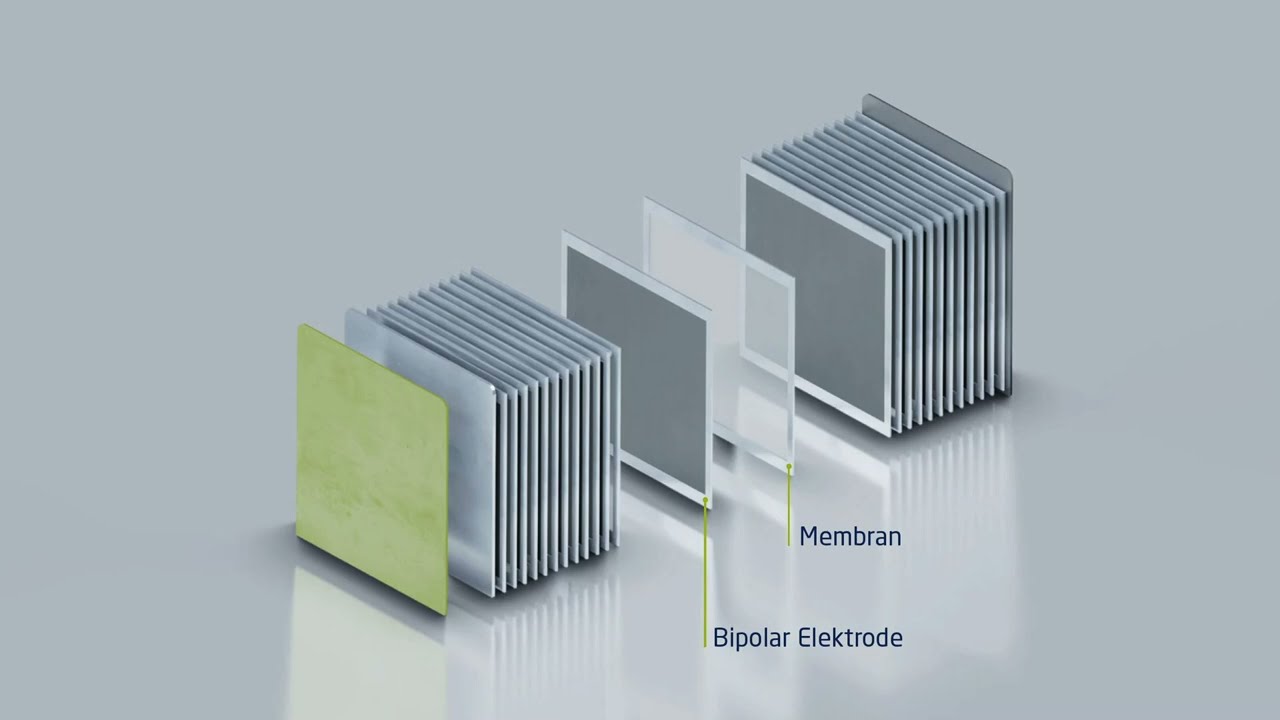

How a Redox Flow Battery works

Malte Thoma: Lowering the production costs of the stack components is necessary and goes hand in hand with scaling production. Another possibility is to make the stacks more efficient, which means more performance for the same money. What is Schunk's contribution in this regard?

Hartmut Groß: The design of the stack and the technology itself are the responsibility of our customers. However, we know very well what role the bipolar plate and its material properties play in the interaction with the electrode materials as well as the electrolyte and the membrane. In joint development projects, some of which are publicly funded, we optimize the stack design and adapt the material of the graphite bipolar plate accordingly. In particular, the contact resistance or the improved electrical conductivity of the bipolar plate are the subject of current developments.

Dr. Groß, how do you advise your customers?

Hartmut Groß: Schunk offers various graphite materials. On the one hand, there is the thermoset-bonded material as in our fuel cell applications. On the other hand, we have developed a thermoplastic-bonded graphite material. This has the advantage that it can be produced inline in a continuous extrusion process and is available as thin foils in rolls. If required, it can be made up to square meter size. The thermoplastic material also allows the film to be welded to the frame of the stack without the need for additional sealing. This makes the product attractive in terms of cost.

The disadvantage of this material solution is that the effect on sheet resistance is quite a bit higher compared to our thermoset bonded product. This is the reason why we are working intensively on smaller contact resistances.

How do redox flow stack manufacturers select Schunk's materials? Are there companies that use both grades in one stack?

Hartmut Groß: Not really. Most of our customers follow a certain design philosophy. Either they want to produce cells with high power density - in which case they need high conductivity and low resistance. Such customers use our thermoset, compression-molded material.

Other customers are satisfied with a medium power density, for example less than 200 mW/cm² instead of 400 to 600 mW/cm², and are looking for large cell area and low cost. For these customers, our flexible, extruded film is an attractive solution. It has already proven itself in electrochemical tests.

Dr. Thoma, let's come back to your pilot project. What is your experience with redox flow batteries so far? Will you have more demand in the future? What are the next steps?

Malte Thoma: We have successfully completed the pilot project. We had no problems in operation and we see the benefits.

We have now entered the next phase and are in the process of developing battery projects with various interested electricity customers. Unfortunately, I can't reveal anything concrete about that today. But it is clear that redox flow batteries will play a role in this context.

Dr. Thoma, what recommendation do you have for a component supplier like Schunk when it comes to other future stationary energy solutions?

Malte Thoma: In my opinion, redox flow batteries are a great technical solution for stationary applications with advantages over other technologies. However, LCOE, Levelized Cost of Energy, is one of the most important decision factors now and in the future. I strongly recommend system manufacturers to work closely with all component manufacturers to develop and offer reliable and cost effective solutions. Then I have no doubt that redox flow batteries will play a significant role in the future energy industry.

Thank you very much, Dr. Thoma. How about you, Dr. Groß? Is there anything you would like to add?

Hartmut Groß: I think we have worked out the main arguments and can say that redox flow batteries will play a crucial part in the future energy mix - provided that,

- the performance of the batteries is competitive

- the systems are reliable over their lifetime and require little maintenance,

- operation is cost-effective and CAPEX, the cost per megawatt-hour/system, is competitive.

Schunk graphite materials ensure the high performance and long life. Costs will come down with volume, i.e. quantities, and experience in mass production. Schunk is also prepared to invest further in growth by adding additional production lines as needed.