13. Oktober 2023

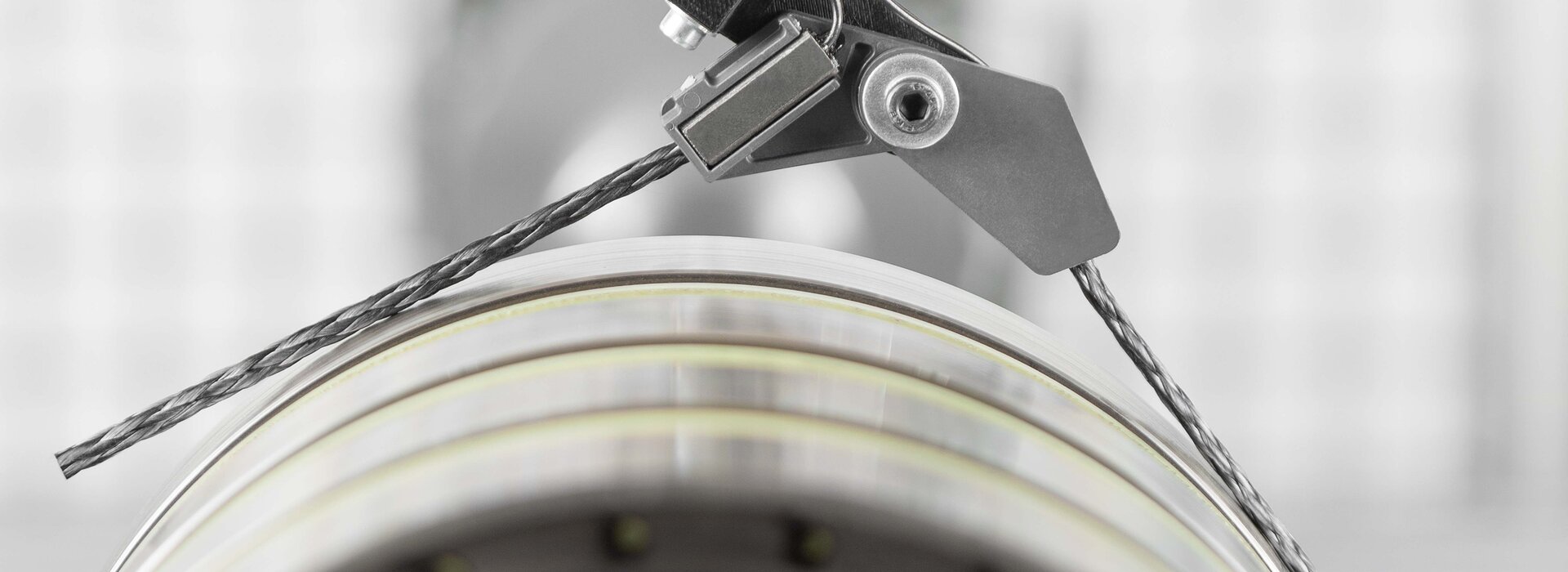

When the 2:45 p.m. ferry arrived on the Isle of Wight on November 19, 2020, a very special passenger disembarked: the first of a total of five trains for the completely refurbished fleet of the modernized Island Line. The trains thus continue the Island Line‘s long-standing tradition of using refurbished and rebuilt London Underground equipment. Adrian Handley, Sales and Marketing Director of Sabre Rail, the UK's leading independent specialist in the overhaul of rail systems and components, shares the challenges the vehicle manufacturer faced in order to be able to operate the trains on the island and the solution that was developed together with Schunk. (Image below: The first Island Line Class 484 train arrives at Wightlinks Fishbourne ferry terminal. © James123pilbeam, license.)